Our Winemaking Philosophy

We preserve our wines’ cool-climate aromas and flavors through gentle handling, small-batch methods, and a hands-on approach.

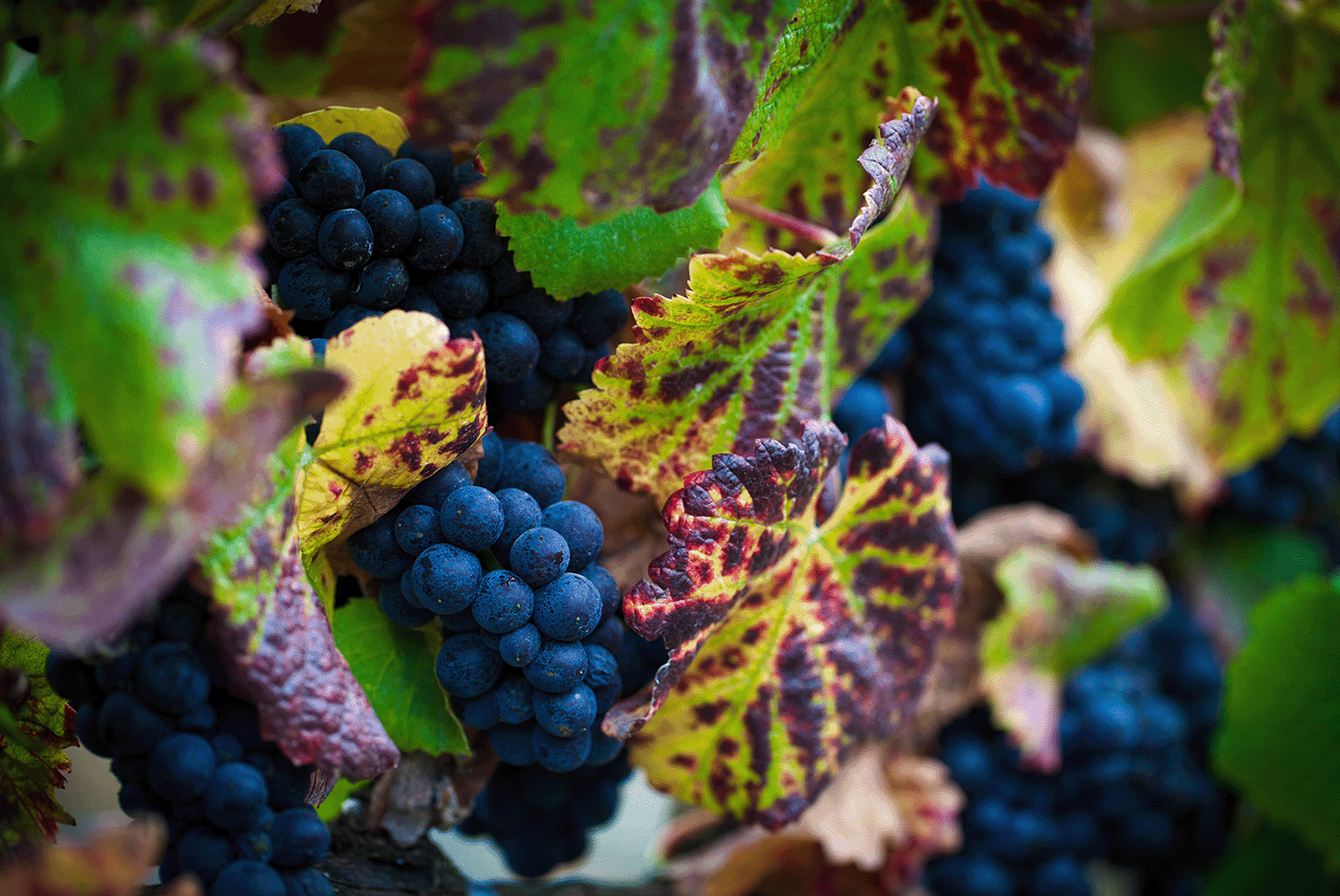

HARVESTED WITH CARE

We prefer to pick grapes in the coolest hours of the day (or night), and handle them tenderly to ensure the clusters arrive at the winery in prime condition.

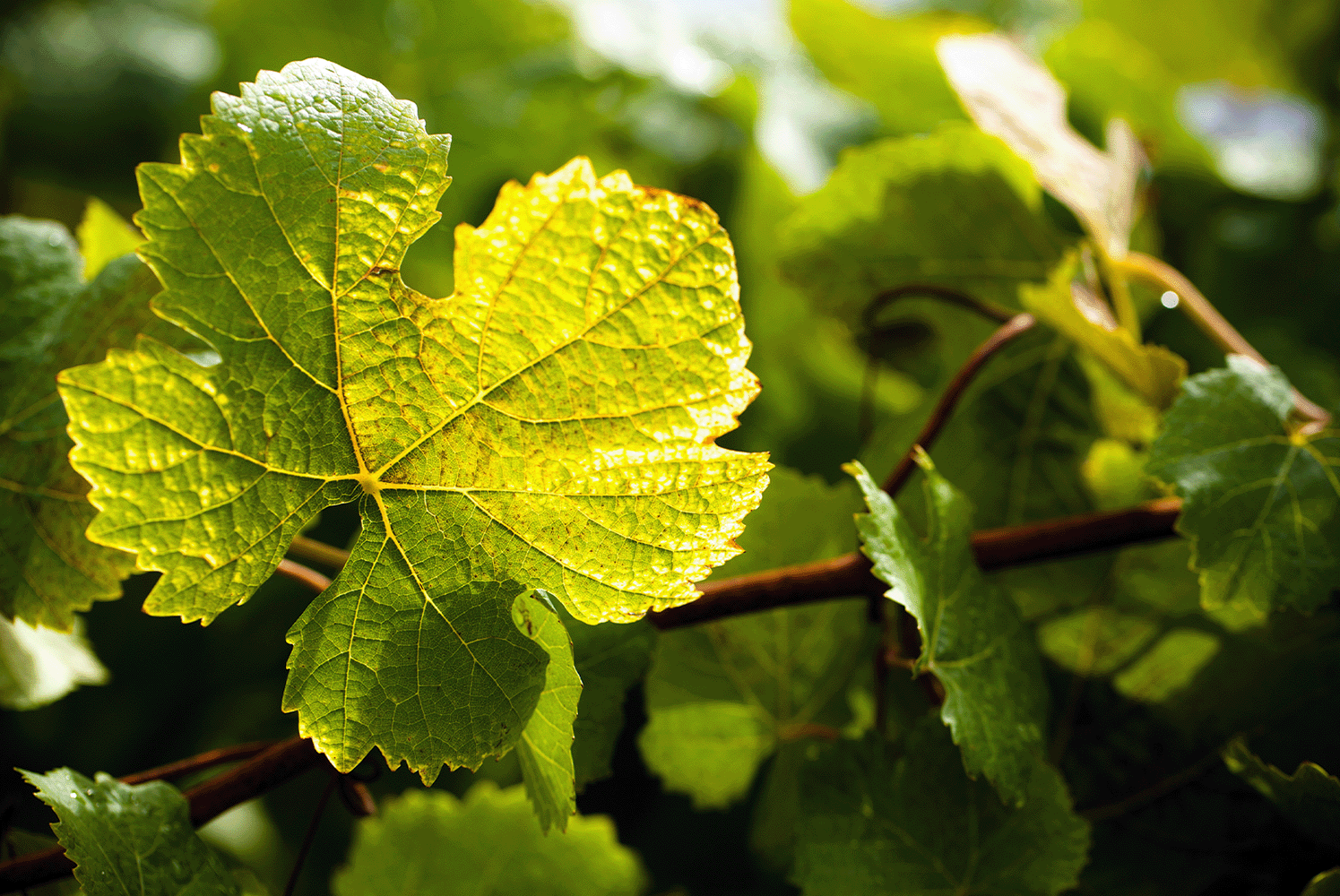

When is a grape ready to harvest? While statistics like Brix (a measure of sugar content) can guide the decision, nothing compares to tasting the grapes themselves. Throughout the season, Winemaker Craig McAllister and his team visit the vineyards daily, searching for complex flavors in the grapes and tasting the seeds, which turn from green to brown as they ripen, developing a biscuity flavor.

THE TEAM BEHIND THE WINE

Naturally, our winemaking team seeks to express the essence of the terroir in our wines, capturing the unique personality and flavor profile of the vineyard. Craig McAllister infuses our winemaking regime with a highly personal touch that combines the best of traditional Burgundian winemaking techniques with a contemporary California style.

CHARDONNAY WINEMAKING

When Chardonnay arrives at the winery, the grapes move via conveyor belt to the press. To best capture the fresh fruit character, we gently compress whole clusters, which minimizes any bitter compounds from the skin, seeds, or stems.

We ferment our Chardonnay in oak, and stir the lees (yeast deposits) by hand twice a month to create a rich texture on the palate.

PINOT NOIR WINEMAKING

Pinot Noir grapes are hand-sorted at the winery. Any clusters with green or overripe grapes are removed, along with any stems, leaves, or other MOG (material other than grapes).

After destemming, Pinot Noir is given a "cold soak," resting in chilled tanks for three to five days. As the grape juice, which is clear, steeps in the deep purple grape skins, it takes on a gorgeous, luminous color.